PA

One, Introduction to PA

Nylon, also known as nylon, scientific name polyamide fiber (polyamide fiber), is named after it was born in Jinzhou, China. It is an early industrialized synthetic fiber variety in the world. It is called nylon internationally (Nylon's Chinese transliteration, on is taken from cotton) .

Two, the characteristics of PA

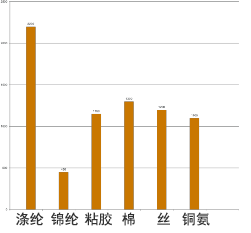

1. Good wear resistance

The abrasion resistance of PA ranks first among all fibers, 10 times that of cotton, 20 times that of wool, and 140 times that of wet viscose fiber. High strength, 1-2 times higher than cotton and 3 times higher than viscose fiber.

2. Light texture

|

Fiber |

Density |

Fiber |

Density |

|

Polyester |

1.38-1.39 |

wool |

1.30-1.32 |

|

Nylon |

1.14-1.15 |

Down (downer branches) |

1.144 |

|

Viscose fiber |

1.52-1.53 |

cotton |

1.54-1.55 |

|

Acrylic |

1.14-1.19 |

Ramie |

1.54-1.55 |

|

Polypropylene |

0.91 |

Acrylic |

1.23-1.28 |

|

Vinylon |

1.26-1.30 |

Aramid 1313 |

1.38 |

|

Spandex |

1.0-1.30 |

Aramid 1414 |

1.47 |

3. Soft texture (small modulus of elasticity)

4. Good moisture absorption and dyeability

The hygroscopicity of PA is better among common synthetic fibers, and the moisture regain is about 4.5 under normal atmospheric conditions, which is much higher than 0.4% of polyester. The dyeability of PA is also good, and it can be dyed with acid dyes, dispersing materials and other dyes.

|

Fiber type |

Regular moisture regain |

Fiber type |

Regular moisture regain |

|

Raw cotton |

8.5 |

Viscose |

13 |

|

Homogeneous scouring wool |

16 |

Polyester |

0.4 |

|

Heterogeneous scouring wool |

15 |

Nylon |

4.5 |

|

Mulberry Silk |

11 |

Acrylic |

2 |

|

Ramie, flax |

12 |

Vinylon |

5 |

|

Jute |

14 |

Polypropylene, polyvinyl chloride |

0 |

5. Natural coolness

|

Fiber |

Thermal conductivity (W/m.℃) |

Fiber |

Thermal conductivity (W/m.℃) |

|

Cotton |

0.071-0.073 |

Nylon |

0.244-0.337 |

|

Silk |

0.05-0.055 |

Polyester |

0.084 |

|

Wool |

0.052-0.055 |

Acrylic |

0.051 |

|

Viscose |

0.055-0.071 |

Polypropylene |

0.221-0.302 |

|

Acetate |

0.05 |

Chlorine |

0.042 |

6. Good resilience

The elastic recovery rate PA at 10% elongation is higher.

PA: 92-99%

Polyester fiber: 67%

Acrylic fiber: 56%

Vinylon fiber: 45-50%

Viscose fiber: 32-40%

Three,introduction of differentiated functional nylon staple fiber

1. High-strength nylon staple fiber

The high-strength fiber produced by special technology and equipment has a breaking strength ≥6.5cN/dtex, which can greatly improve the breaking strength of the blended yarn, the breaking strength and the tearing strength of the fabric.

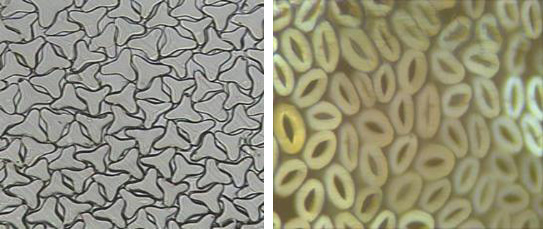

2. Different cross-section PA

Through the research of simulation and bionics, special spinnerets are customized to produce polyamide staple fibers with irregularities such as triangular, Y-shaped, cross-shaped, and hollow-shaped. It is applied to clothing fabrics to give new properties such as diamond-like luster, or anti-pilling, or moisture absorption and perspiration, or silkiness, and expand the scope of product application.

3. Light-absorbing and heat-storing nylon staple fiber

By adding nano-materials, the fiber can absorb the high-energy band of sunlight and visible light (the energy of 0.3-2.0um accounts for 95% of the total), which converts thermal radiation into heat energy efficiently, and at the same time almost completely reflects the low-energy band of the human body (wavelength is 10um) , To achieve heat storage and warmth.

4. Cold antibacterial nylon staple fiber

The fiber contains mineral powder that can quickly release cold, which increases the heat dissipation rate. At the same time, it adds an antibacterial agent that is harmless to the human body, so that the fiber has a composite function of cooling and antibacterial at the same time. When the fabric processed with this fiber's heat dissipation and antibacterial properties touches the skin, the wearer can maintain a cool and comfortable feeling while eliminating the possibility of odor.